Explain the Different Types of Welding Positions With Neat Sketch

The 9 Types of Welding 1. The neutral flame burns cleanly and is used for most welding applications.

What Are The 4 Basic Welding Positions And When Should You Use Them Millerwelds

This heat is further used to melt interface surfaces of welding plates which are held together to form a joint.

. Flux-Cored Arc Welding FCAW 3. Different Kinds of welding Positions GROOUL Face Groove angle -FOOT Root gap - Root face Fillet WeLDS a Flat Positions b HORIZONtal P Positions P 2 Horizontal P1 WELDING P 2 Vertical Positions d over Head positions P2 PI vertical axis Generally over P1 Plate 1 the Head P2 Plate 2 2 Attachments jpg jpg Comments 1. Laser Beam Welding 6.

Types of welding defects associated with the corner joint are lamellar tearing incomplete penetration porosity slag inclusion etc. Pipe welding can be done under many different requirements. Carbonizing flames are cooler and often used when working with steel or iron.

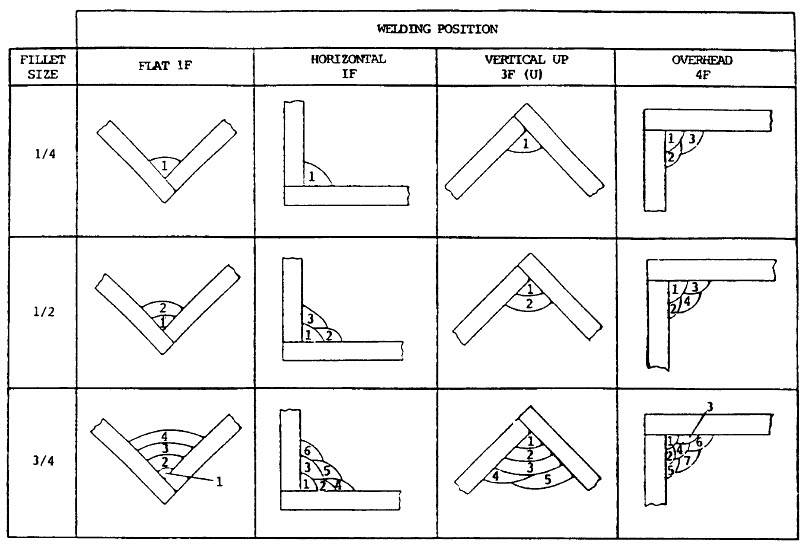

This process can be done with or without help of filler material. In this process mostly oxy-acetylene gas is used as fuel gas. Flat Position 1G and 1F Horizontal Position 2G and 2F Vertical Position 3F and 3G Overhead Position 4G and 4F 1.

But you also do surface welds in all four positions as well thought you will not do this type of weld very often. GROUP- 2 i Explain any one type of spanner with neat sketch. TIG Gas Tungsten Arc Welding GTAW 2.

5 x 3 15 Marks A. Similar to tee joints. Flat welding horizontal welding vertical and overhead welding groove weld edge preparation 231 Welding position The welding positions are classified on the basis of the plane on which weld metal is deposited.

The positions flat horizontal vertical and overhead are the basic types of welding positions. Welders can perform these two welds in all four positions. The four main types of welding are.

First week only 499. Discuss the different types of Thread forms with neat sketch along with its applications. The tee joint is as the name describes a joint in the shape of a T.

Atomic Hydrogen Welding 9. The manner in which the joining occurs is dependant on the exact process used for example friction stir welding FSW friction stir spot welding FSSW linear friction welding LFW and rotary friction welding RFW. Other variations exist as well - for example double-V preparation joints are characterized by the two pieces of material each tapering to a single center point at one-half their height.

Answer the following questions each carries Five Marks. 5 Marks 25 marks 25 marks A. In this post well detail the specifics assigned to each process and highlight the differences among them.

In olden days the process of metal welding can be done by heating the metals and pressed jointly which is known as forge welding method. After this there are different types of welding technologies have been invented like. The four basic welding positions are.

Oxy acetylene or hydrogen welding explained below Air acetylene welding. The five basic types of weld joints are the butt joint lap joint corner joint edge joint and T-joint a variant of this last is the cruciform joint. The position of a particle traveling along a curved path is s.

Iii List the types screw and explain any with neat sketch. However they do not adequately describe pipe welding positions. Flat horizontal vertical and overhead.

Gas Metal Arc Welding GMAWMIG Gas Tungsten Arc Welding GTAWTIG Shielded Metal Arc Welding SMAW and Flux Cored Arc Welding FCAW. One piece of metal lays down flat while another section is welded standing on its. 5 Marks Any five types- 25markssketches applications- 25 marks B.

Following are the four main types of welding positions. Ii Define power tools and prepare list of popular portable power tools. Normally there are four types of welding positions namely horizontal flat vertical and overhead.

Besides this there are special. To minimize the occurrence of these defects a little variation can be applied. The three basic flames used for gas welding include neutral carburizing and oxidizing.

Plasma Arc Welding 8. I Screw thread ii Internal Thread iii External thread. In the 19th century resistance gas and arc welding was invented.

It is used to joint the plates having thickness 3 mm or less. Variations such as grooving the welded metal and using an open corner joint instead of a closed corner joint. This involves welding at the top of the joint.

V Define belt drive and explain any one with neat sketch. But at present the welding technology has been changed by the arrival of electricity. 1 Introduction To Welding 2 Safety In Welding 3 Shielded Metal Arc Equipment Setup And Operation 4 Shielded Metal Arc Welding Of Plate 5 Shielded Metal Arc Welding Of Pipe 6 Shielded.

What are the different types of welding processes and its applications. The Types of Welding Joints. There are five basic types of joints commonly used for fusion arc and gas welding.

2 Explain with neat sketch Gas welding process. The most common type of weld you will do is a Fillet weld and a Groove weld and you can accomplish these welds in all four positions. Flat welding In flat welding plates to be welded are placed on the horizontal plane and weld bead is also deposited.

Principles and Applications MindTap Course List 8th Edition. MIG Gas Metal Arc Welding GMAW 5. These positions well cover in a separate article.

Welding defects are formed in a welding work due to the weak or poor technique used by the inexperienced or untrained welders or due to structural problems in the welding operation. Oxidizing flames are the hottest and least used due to the oxidation of the base material. Start your trial now.

Differentiate the Fusion and Pressure welding process. Assignment1 Explain the Importance of Welding Process. Below are the six types of welding joints.

Flat Position The most obvious type to perform is the flat position sometimes called the down hand position. And the most common types of welds are groove and fillet welds. The lap joint is obtained by over lapping the two plates and welding the edges of the plates.

Friction welding doesnt require the use of. Gas welding is a type of liquid state welding process in which fuel gases burns to generate heat. Fusion welding or nonpressure welding explained below They can also be classified depending on the source of heat as follows.

Stick Shielded-Metal Arc Welding SMAW 4.

Types Of Welding Classification Of Welding Processes Welding Ndt

4 Main Types Of Welding Processes With Diagrams

What Are The 5 Mig Welding Positions A Definitive Guide Welders Lab

5 Types Of Welding Joints And Their Use Complete Guide

What Are The 5 Mig Welding Positions A Definitive Guide Welders Lab

Types Of Welding Positions Welder Portal

Welding Joint Types Butt Joints Lap Joints Tee Joints More

What Is Welding Definition Processes And Types Of Welds Twi

Types Of Welding Joints The 5 Different Types Of Welding Joints

4 Main Types Of Welding Processes With Diagrams

5 Types Of Welding Joints Cliff S Welding Mesa Az 480 832 0570

Types Of Welding Positions Welder Portal

Types Of Joints In Welding Youtube

Fig 1 Effect Of Electrode Angle On Bead Shape A Comparison Of Trailing Vertical And Leading Arcs Metal Working Projects Submerged Arc Welding Welding

What Is Welding Definition Processes And Types Of Welds Twi

Different Types Of Welding Joints The Welding Master

5 Different Types Of Welding Joints Weld Joints Engineering Choice

Comments

Post a Comment